Major Production Equipment List

Volt Former Line

Friction press

Hot automatic forging machine

Hot automatic forging machine

Hot Rolling Machine

Rail spikes point machine

Thread rolling machine

NC lathe

Machining center

Electric discharge machine

High frequency heating device

Heat treatment line

Automatic rack building system

Palletizer

rotary

Main Inspection Equipment List

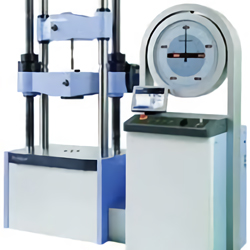

1000 kN Universal Testing Machine

2000 kN Universal Testing Machine

Contraser

Bolt testing machine

Various hardness testers

Metallurgical microscope

Three-dimensional measuring devices

Magnetic particle flaw detector

Manufacturing Process

(Mold Manufacturing)

Design / Drafting

For the production of special shapes and irregular bolts, we will design the molds by ourselves.

Mold Making

Especially the mold used for hot forging is carried out in-house from material procurement to final heat treatment.

Manufacturing Process

(Hot)

Cutting Of Steel

Cut steel bar · coil to the required length.

Mold Making

Especially the mold used for hot forging is carried out in-house from material procurement to final heat treatment.

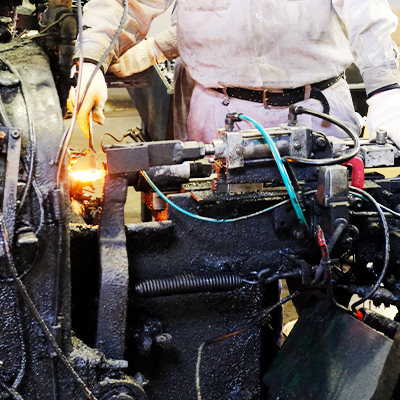

Automatic Forging

Use an automatic forging machine, heat it to soften it, then forge the head.

Shape A Head

When making a rail spikes, point the tip.

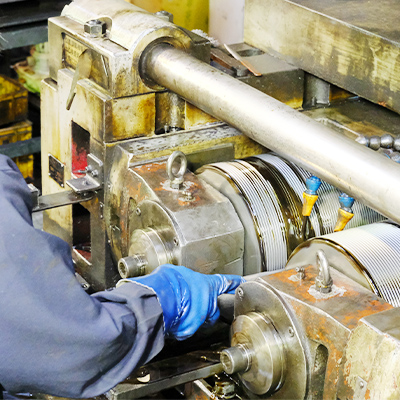

Rolling

Press the trapezoidal screw while pushing forward on the heated material.

Threading

Without heating (cold), screw the same screw thread and valley shape.

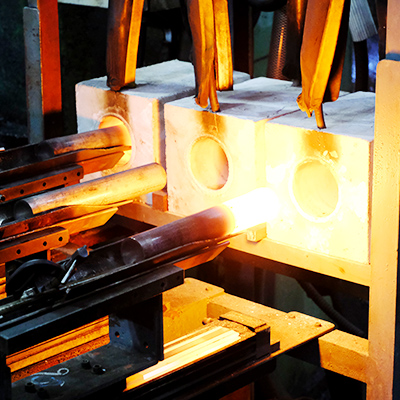

Continuous Heat Treatment Furnace

Check the temperature control strictly and bake the bolt.

Nut Set

We will set accessories according to customer’s request.

Packing

Delivery

Manufacturing Process

(Cold)

Cold Rolling

Apply large molding pressure at room temperature and forge the head.

Rolling

Press the trapezoidal screw pushing forward on the hearted material.